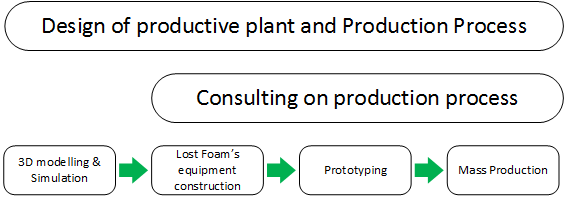

The creation of quality products using Lost Foam depends on deeply knowledge of production process, its continuous optimization but mostly considering the product’s specifications.

PRODUCTS. Design and first-series production of both iron and aluminum parts with quantified performance targets achievable, such as: wall thickness, part integration, reduction of porosity, cost savings, weight reduction, quality level, etc.

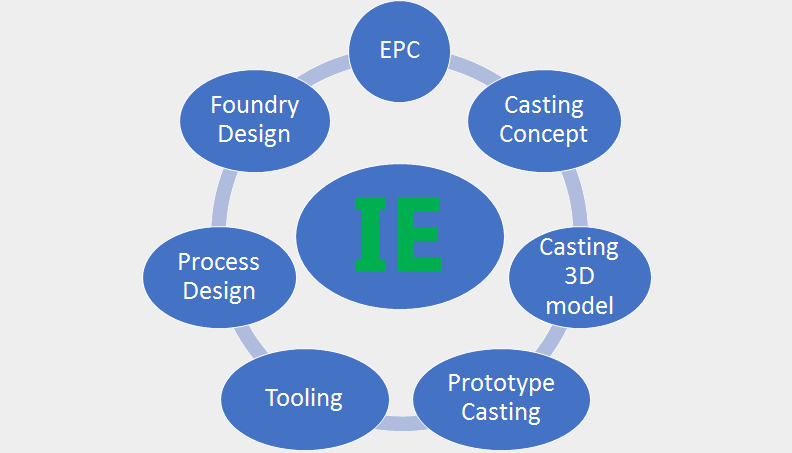

PROCESS. Upgrade of brownfield LF iron foundries, EPC general contracting for greenfield LF iron foundries with quantified performance targets achievable, such as: environmental standards, productivity, industry 4.0, etc.

Isotta Team can assist customer from the early concept phase of the design in order to optimize the ratio cost/value of the casting targeting:

- Robust process, Quality consistency and Low Scrap

- Weight Reduction, Low draft, Wall thickness

- Machining Reduction, Near to shape casting

- Feature integration, Cast in insert, as cast channels